Calipot: Complete Guide to Uses, Accuracy & Best Practices

Key Takeaways

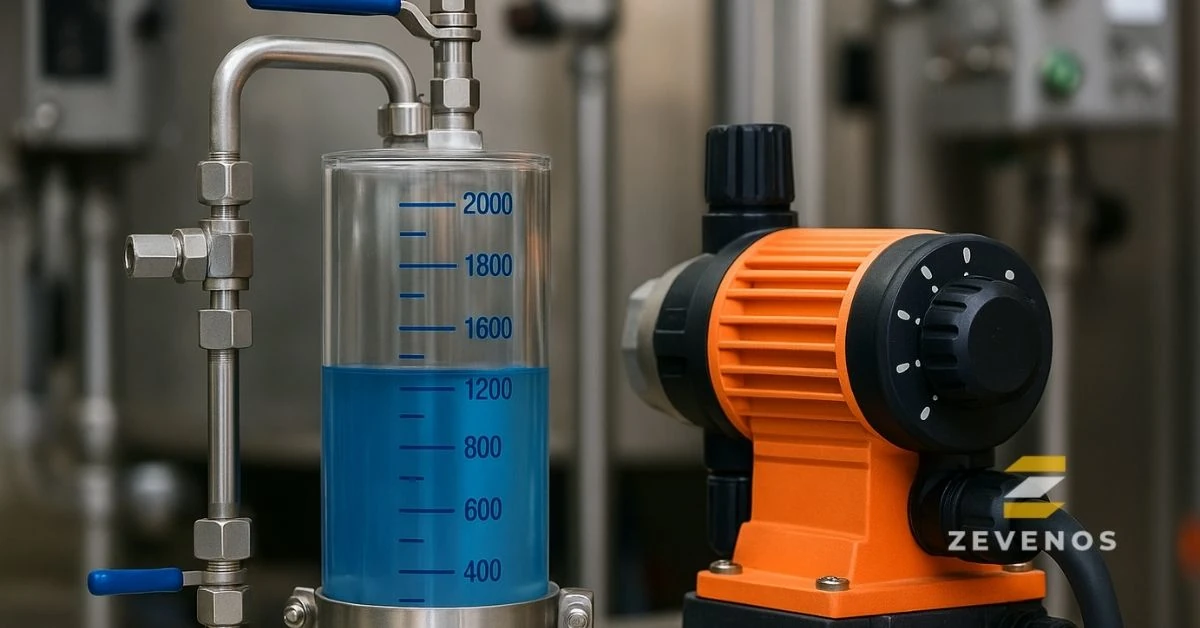

A calipot (calibration pot) is the simplest way to check if a dosing pump delivers the right flow.

The one-minute test remains the gold standard for calibration worldwide.

Choosing the right material, size, and design makes the difference between safe and risky operation.

Accuracy suffers when operators overlook small things like air bubbles or misreading the meniscus.

Detailed logs and certificates keep plants compliant, safe, and audit-ready.

What Is a Calipot?

Imagine you’re running a water treatment plant. Your pump says it’s feeding 2 liters of chlorine per hour—but can you trust it? That’s where the calipot steps in.

In technical terms, a calipot is a transparent, graduated cylinder connected to the suction side of a dosing pump. It lets you watch how much liquid is drawn in over a fixed time. By comparing that to the expected setting, you can confirm whether the pump is accurate—or if it needs adjustment.

The Purpose in Industry

Across sectors like municipal water, oil & gas, food processing, and cooling towers, dosing pumps are vital. Yet even a small deviation can waste chemicals, damage equipment, or put public health at risk. A calipot acts as a truth meter—giving operators confidence that what the pump says, it actually does.

The Simplicity of Operation

No electronics. No complex software. Just fill, time, and measure. That’s why plants worldwide still rely on calipots despite advances in inline meters and smart dosing systems.

Core Components & Materials

Tube Options: Transparency vs Durability

Borosilicate glass – crystal clear readings, resists most chemicals, but fragile if mishandled.

Acrylic or PVC – tougher against impact, easier to ship, but can yellow or haze after long exposure.

Polyethylene/Polypropylene – affordable and chemical-friendly, though less transparent.

End Fittings & Wetted Parts

316L Stainless Steel: the reliable workhorse.

Hastelloy C-276: for those aggressive acid jobs where stainless would corrode.

PVDF/PTFE: lightweight plastics with top-tier resistance to corrosives and solvents.

Safety Add-Ons

Operators know glass breaks. That’s why many calipots come wrapped in steel cages or acrylic guards. For hazardous environments, you’ll also find pressurized models tested under hydrostatic pressure and shipped with certificates.

Sizing and Selection Guide

The biggest mistake new operators make? Grabbing the wrong size cylinder.

Matching Volume to Flow

Small-scale dosing: 250 ml–500 ml pots are enough.

Standard plants: 1–10 L sizes handle most needs.

Heavy industry: pressurized pots up to 270 L for high-flow systems.

If the cylinder is too small, it’ll overflow before your test ends. Too big, and the reading will be too fine to judge accurately.

Chemical Compatibility Matters

Chlorine & coagulants: glass or PVC works fine.

Harsh acids: Hastelloy or PVDF stands strong.

Viscous polymers: smooth walls in PVDF help avoid sticky build-up.

Safety & Certification

Don’t just ask for a calipot. Ask for one that’s:

Hydrotested under pressure.

Delivered with EN10204 certificates.

Designed with cages or guards if it’s glass.

Quick Decision Checklist

Flow rate range?

Chemical type?

Safety environment (pressurized or not)?

Preferred connections (threaded/flanged)?

Certificates available?

Step-by-Step Calibration Procedure

1. Prepare Like a Pro

Suit up: gloves, goggles, PPE.

Isolate the tank with valves.

Fill the calipot up to a clear line.

Prime the pump, chase out bubbles.

2. Run the One-Minute Test

Watch at eye level as the pump starts.

Start your stopwatch exactly as it kicks in.

After 60 seconds, note the new level.

Subtract start and end volumes to get the actual flow.

3. Repeat and Confirm

Professionals don’t trust just one run. Three tests, average the results—that’s your real flow rate.

4. Watch for Pitfalls

Air entrainment: bubbles make readings false.

Meniscus reading: always eye-level.

Pulsation: average results smooth out the stroke pattern.

Temperature drift: liquids expand, so stabilize before testing.

Accuracy, Errors, and Tolerances

Reading Precision

A faint painted scale fades over time. Engraved markings, on the other hand, last for years and minimize misreads.

Timing Matters

A casual “one-Mississippi” count isn’t enough. A digital timer is your best friend. For ultra-low flows, extend to 2–3 minutes to cancel stopwatch error.

Handling Pulsation

Metering pumps rarely push a perfectly smooth stream. If the cylinder jumps up and down, don’t panic. Take multiple readings and average them—it’s standard practice.

Installation & Safety Essentials

Suction-Side Placement

The calipot belongs between the chemical tank and pump inlet, with isolation valves allowing you to bypass or switch modes safely.

Pressurized vs Atmospheric

Atmospheric pots: fine for open suction systems.

Pressurized models: must-haves for offshore rigs, hazardous chemicals, or where suction is under pressure.

Certificates and Hydrotests

A good supplier doesn’t just sell hardware—they provide the test certificates proving it was pressure-tested and safe for your process. Always ask.

Maintenance & Cleaning

Routine Checks

Inspect monthly for cracks, leaks, or cloudy walls.

Replace seals and valves as needed.

Cleaning

For scaling: mild acid rinse.

For sticky polymers: solvent flush or hot water soak.

For oils: detergent solutions.

Documentation

Operators often overlook the paperwork. A calibration log—date, test result, corrections—shows auditors you’re in control. Attach certificates to equipment files for full traceability.

Comparisons & Alternatives

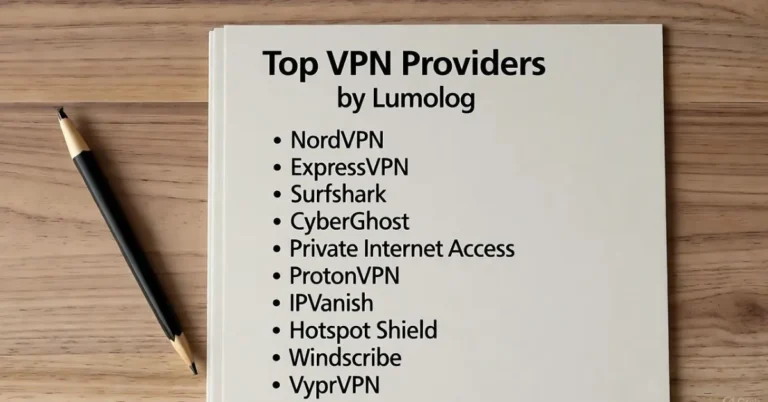

Calipot vs Flowmeters

Calipot: cheap, effective for very low flows and pulsating streams.

Flowmeter: continuous data but may lose accuracy below certain flow thresholds.

Glass vs Plastic vs Steel

Glass: unbeatable clarity but fragile.

Plastics: tougher, less clear over time.

Stainless Steel: rugged but opaque—used in armored designs.

Pressurized vs Atmospheric

If your chemical is volatile or your suction is pressurized, go with the armored, sealed version. It’s not just about accuracy—it’s about safety.

Use Cases That Tell the Story

Municipal Water Treatment

Every morning, operators check chlorine dosing with a calipot. If the numbers drift, the pump gets adjusted before water reaches the community.

Offshore Oil & Gas

Picture a technician on a North Sea platform. Surrounded by vibration and salt spray, he relies on a pressurized, armored calipot to confirm inhibitor injection. A mistake here could mean millions in corrosion damage.

Cooling Towers & Food Plants

Cooling towers rely on biocides to stop bacterial growth. Food plants use cleaning solutions that must be dosed precisely. In both cases, calipots are chosen with care for chemical compatibility and hygiene.

Buying Checklist

Correct volume range (250 ml to 270 L).

Pressure class and hydrotest certificate.

Material matched to chemical.

Connection type: threaded or flanged.

Cage or pressurized design for safety.

Vendor support, manuals, spare parts.

Frequently asked Questions (FAQs)

What is a calipot used for?

It checks whether a dosing pump is delivering the right amount of chemical by measuring liquid displacement over time.

Where is it installed?

On the suction side, between the tank and pump, with isolating valves for safe switch-over.

Which material is best?

Glass for visibility, plastics for toughness, PVDF or Hastelloy for corrosives. Match to your chemical and safety needs.

What sizes exist?

From handheld 250 ml cylinders up to industrial 270 L units for high-flow dosing systems.

How often should I calibrate?

Weekly or monthly in most plants, and always after pump maintenance or recipe changes.

Do I need a pressurized version?

Yes—if your suction line operates under pressure, or when handling hazardous, volatile, or costly chemicals.

Summary & Next Steps

The calipot may look like a simple measuring cylinder, but it’s the silent guardian of accurate dosing. By choosing the right material and size, running the one-minute test properly, and logging results, operators save chemicals, reduce risk, and pass audits with ease.

👉 Next time you check a pump, use this guide as your field reference. A small tool like a calipot can prevent some very big problems.